System Architecture & Integration:

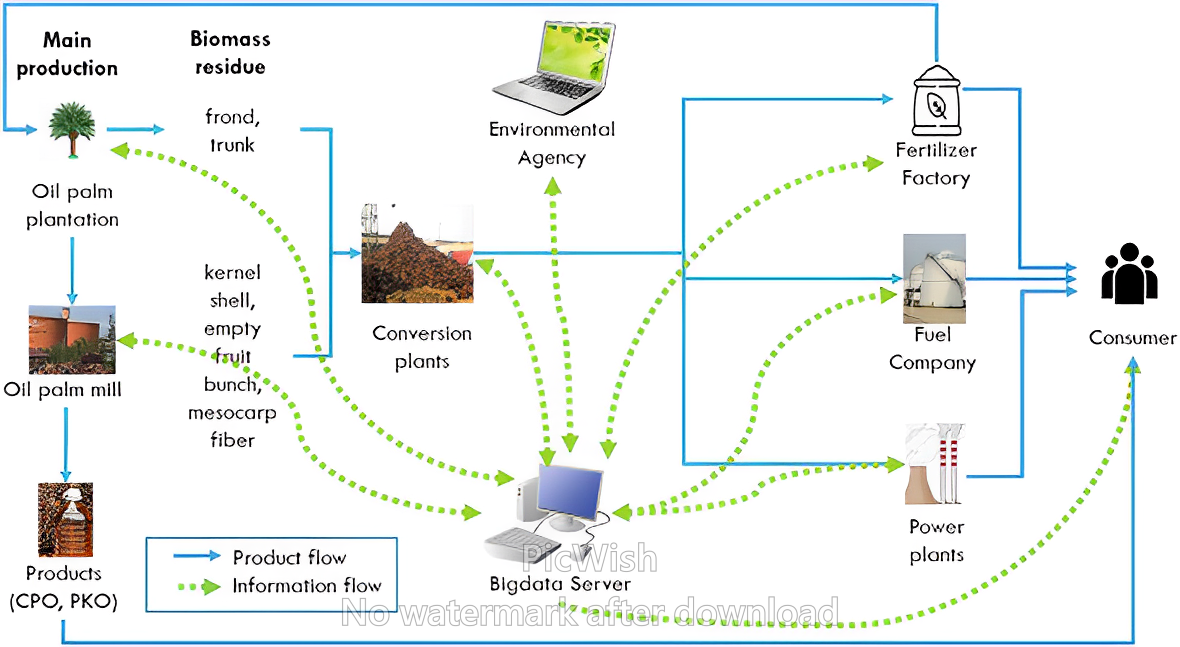

The software is built on a centralized, scalable platform that collects, stores, and analyzes data from multiple production plants. It integrates with plant-level control systems (SCADA, MES, ERP) via secure communication protocols (e.g., OPC UA, MQTT, REST APIs) and uses real-time data acquisition to provide a unified dashboard. Key features include:

Data Aggregation:

Collects data from sensors, PLCs, and ERP systems across all plants for holistic visibility.

Real-Time Monitoring & Reporting:

Provides dashboards and automated reports, enabling quick decisions on production performance and maintenance.

Analytics & KPI Tracking:

Utilizes advanced analytics and machine learning to forecast production trends, optimize processes, and monitor key performance indicators (KPIs).

Modular Design:

Supports customization for different plant types (e.g., palm oil mills, chemical plants) with configurable dashboards and modules for specific process parameters.

Remote Access & Control:

Allows management to monitor plant operations remotely and receive alerts on critical issues, ensuring quick response to anomalies.